Centrifuge / Spin Galvanizing

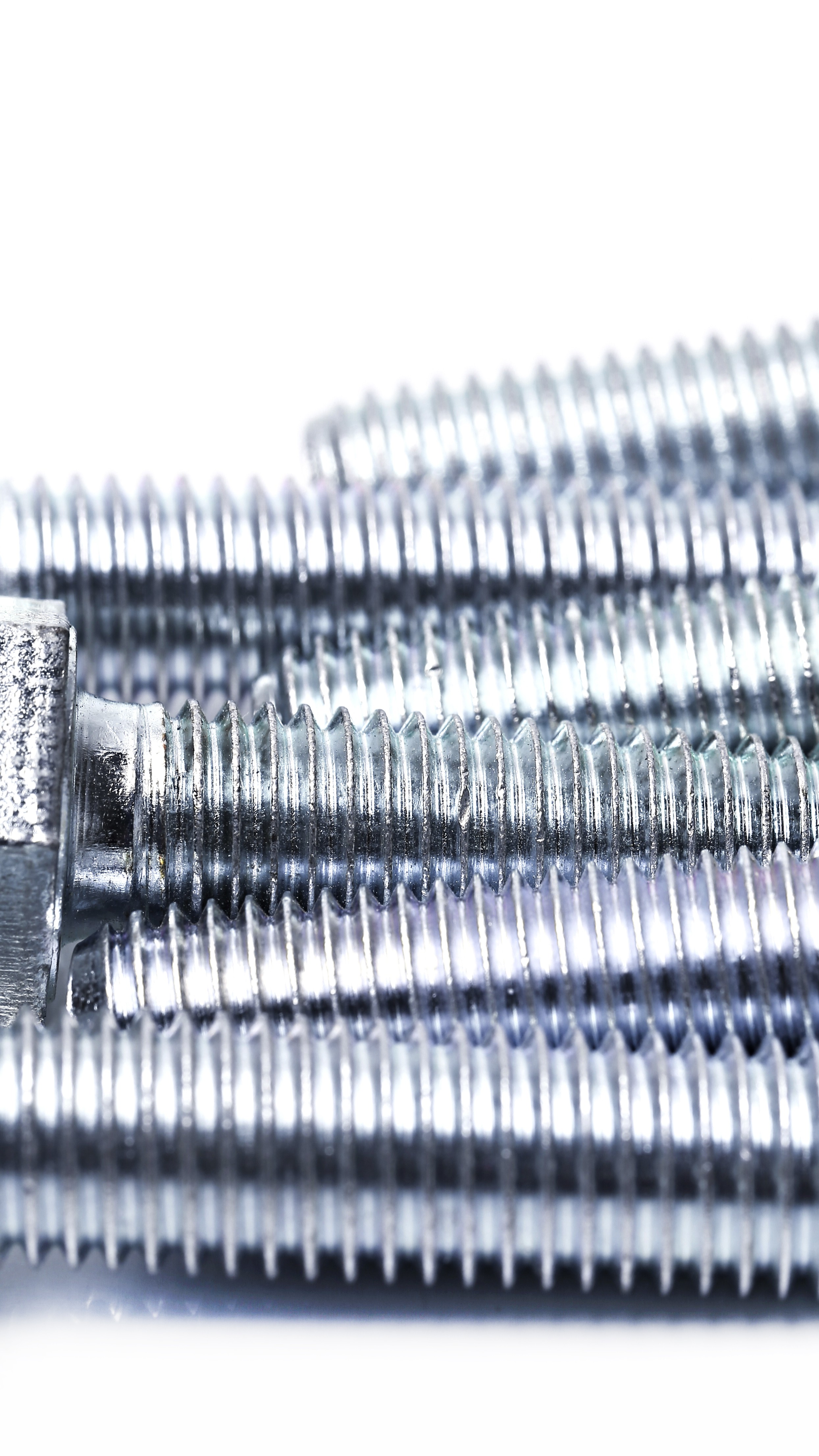

At Pure Metal Industries, we specialize in centrifuge/spin galvanizing for smaller steel components such as nuts, bolts, fasteners, stampings, castings, and other hardware items. This process is performed in strict conformance with ASTM A153 & ISO 1461, making it ideal for parts that require precise coating and a smooth finish, while ensuring that no excess zinc remains in threaded areas.

The Process

Spin galvanizing follows the traditional hot-dip galvanizing process, with a key difference: steel parts are placed in baskets to prevent loss in the molten zinc bath. After dipping, the basket is placed in a centrifuge, where it is spun. This step effectively removes excess zinc, ensuring that components are free from clumping or sticking together. This is especially important for threaded parts like fasteners, where a clean, clear thread is critical for proper functionality.

Our centrifuge galvanizing process ensures high-quality, consistent finishes, with meticulous attention to detail, even for the smallest components.

International Standards

We adhere to ASTM A153 and ISO 1461 standards for hot-dip galvanizing, which also cover spin galvanizing applications. These internationally recognized standards ensure that our centrifuge galvanizing services meet the highest benchmarks for corrosion resistance, durability, and coating uniformity.